Affordable Continuous Automated Vibration Machine Monitoring to

Eliminate Costly Unplanned Downtime

Achieve a drama-free, no-surprises operation.

Schedule a DemoIdentifying Machine Failures Shouldn’t Happen By Chance

If you don’t have an expert to constantly monitor your machines, you might miss something and it’s going to cost you...

You’ll have unnecessary repair cost

Your customers won’t get products on time

You're constantly putting out fires

You’ll put your employees at unnecessary risk

You’ll lose production time you can’t get back

You’ll create scrap material

You don’t have to rely on an expert to monitor your machines periodically. Using the power of Analyst Inside you get more accurate around the clock monitoring with actionable recommendations on how to correct machines problems that are detected – and you’ll actually know what’s wrong to avoid unplanned downtime.

Operate with Confidence and Get Real-Time Insights Into Your Machine Operation with Analyst Inside

Schedule a DemoAvoid Disasters

Stop reacting to disasters and prevent them instead with advanced warnings when machines have issues.

Save Money on Machine Maintenance

Address small problems before they become costly.

Achieve Drama-Free, No-Surprise Operation

Eliminate unplanned downtime and keep your plant running smoothly.

How it Works

Gather Vibration Data

Get real-time vibration data from your machines.

Continuously Analyze Data

Analyze the data 24/7 using standard vibration analysis techniques.

Get Actionable Alerts

Receive notifications when a machine issue is detected & recommendations to address the issue.

Nothing is more frustrating than having all of your hard work, planning, and diligence undone by unplanned downtime

Saved over $18 Million in Unplanned Downtime

Over 30 Years of Industrial Automation Experience

Patented Technology Uses 20+ Proven Vibration Analysis Techniques

Automated Vibration Machine

Monitoring Options

Monitoring Options

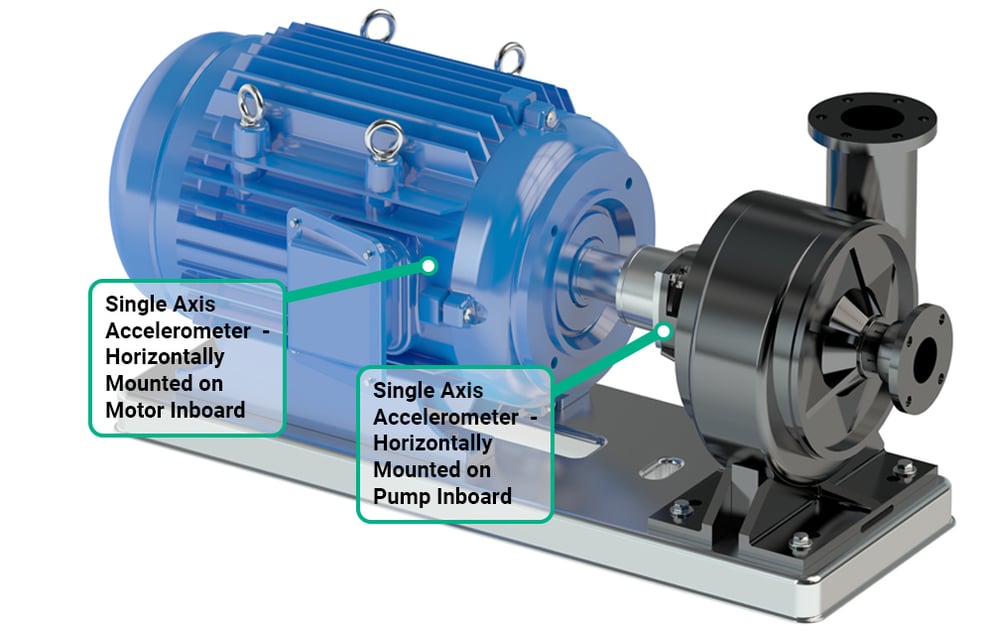

Basic Monitoring

Monitor two points with single axis accelerometers, mounted on the motor and load OR both on the motor. Sufficient to monitor and detect issues before they result in unplanned downtime.

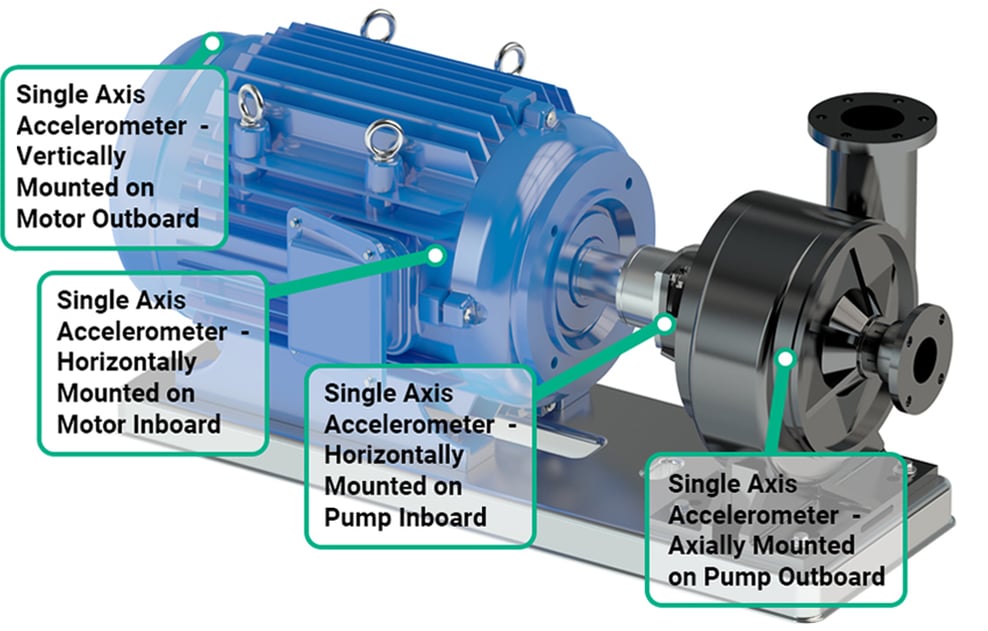

Monitoring OptionsAdvanced Monitoring

Monitor four to six points, minimum of two on the motor and two on the load to provide additional coverage of machines that have a higher cost of failure if they go down. With the additional monitoring points, you will be able to detect issues sooner.

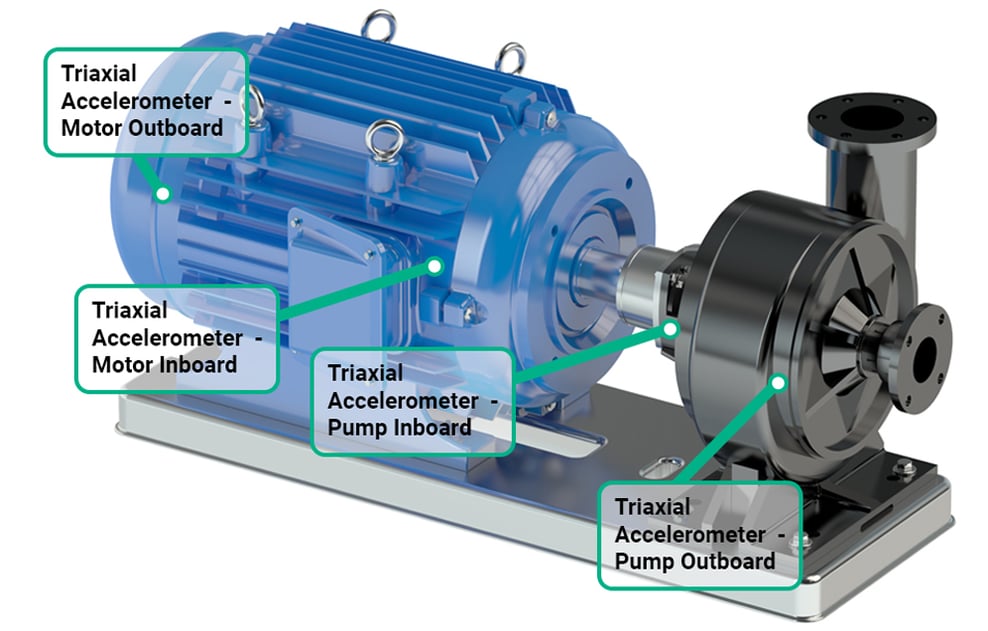

Monitoring OptionsCritical Monitoring

By using triaxial accelerometers (which measure three points of vibration --- one each in the x-y-z axis), measure six points on the motor, and six points on the load to provide complete coverage of your most critical assets. With the additional monitoring points you will be able to detect issues sooner and have more detailed information on what needs attention.

Stop reacting to machine issues and take control with Analyst Inside

If you don’t know your machine has an issue, you can’t fix it. And when you can’t fix it, it will fail at exactly the wrong time. By deploying Analyst Inside, you can detect issues that are developing BEFORE they lead to costly unplanned downtime. The result is a plant that runs as you planned with no surprises.

You may already be using a vibration monitoring service, gathering the data once a month and waiting for the data to be analyzed, leaving you vulnerable to a machine developing a problem that will get missed. Analyst Inside continuously gathers and analyzes vibration data. As soon as it detects something that needs your attention, it sends you an email or text notification. Think about it, when was the last time you were notified that your machine was going to fail in the middle of the night by your outside vibration monitoring services firm?

Maybe you already realized this and took a look at a continuous monitoring system. What you discovered was that the high-end systems were really expensive, difficult to set-up, and still relied on a specialist to analyze the data and provide recommendations. The cost-benefit just didn’t work out. Or maybe you found a simple monitoring solution that didn’t cost as much as a high-end system but it didn’t catch problems soon enough.

With Analyst Inside, you’ll get a system that costs about the same (and in many cases less!) as a vibration monitoring service over the life of your equipment. You’ll still get the benefit of continuous monitoring and analysis to alert you to issues you can address before they cause unplanned downtime.

Analyst Inside works by automating all of the analysis techniques that a certified vibration analyst would do. Once the physical installation of the sensors has taken place, Analyst Inside only takes a few hours to set-up and start monitoring. You don’t have to be a vibration expert to get started.

In many cases, Analyst Inside will begin detecting latent machine issues sooner than a monthly vibration service ever would.

And if you are worried that this is some cloud-based solution where your data will be beamed out of the plant, fear not! Analyst Inside resides in the plant and all data stays on the module. It’s your data, you decide how to use it and where to send it. Unlike other solutions, there is no monthly monitoring fee to worry about (and the real possibility of losing access to historical data if you decide to stop paying for the service). You buy the equipment once. It’s yours, and so is your data.

You deserve to have a drama-free, no-surprises operation, so schedule a 30 minute demo to learn more.

Schedule a DemoRead More