Affordable Continuous Automated Vibration Machine Monitoring to

Uncover Problems Before They Bring Down Production

Analyst Inside is your always on detection system to help you do your job better.

Schedule a DemoIt Doesn’t Have To Feel Impossible to Get an Early Warning on Machine Failures

Get in front of problems before they result in unplanned downtime. Without an early warning on potential machine issues, you might not be able to address them in time…

You have machines going down in the middle of production

You’ll have small repairs turn into major repairs

You’ll suffer long term damage to the machine

You have production you need to scrap

You’re scrambling to get machines back on line

You’ll burn out your maintenance crews when everything is a crisis

You don’t have to rely exclusively on a preventive maintenance program to help keep machines running smoothly. With Analyst Inside, you’ll get alerted to problems that have developed in between maintenance cycles with actionable recommendations on what needs to be done. You’ll keep those machines running and avoid unplanned downtime.

Get The Information You Need to Keep Your Machines Running With Analyst Inside

Schedule a Demo

Avoid Interrupted Production

Eliminate unplanned downtime and keep production running.

Save Money on Machine Maintenance

Address small problems before they become major repairs.

Avoid Fire Fighting

Stop reacting to issues and get proactive in solving them.

How it Works

Gather Vibration Data

Get real-time vibration data from your machines.

Continuously Analyze Data

Analyze the data 24/7 using standard vibration analysis techniques.

Get Actionable Alerts

Receive notifications when a machine issue is detected & recommendations to address the issue.

You’ve got enough to worry about to keep your machines running without an unexpected issue sending you into fire-fighting mode

Save on average two unplanned downtime events per year per machine

Over 30 Years of Experience in Industrial Machine Operation

Patented Technology Uses 20+ Proven Vibration Analysis Techniques

Automated Vibration Machine

Monitoring Options

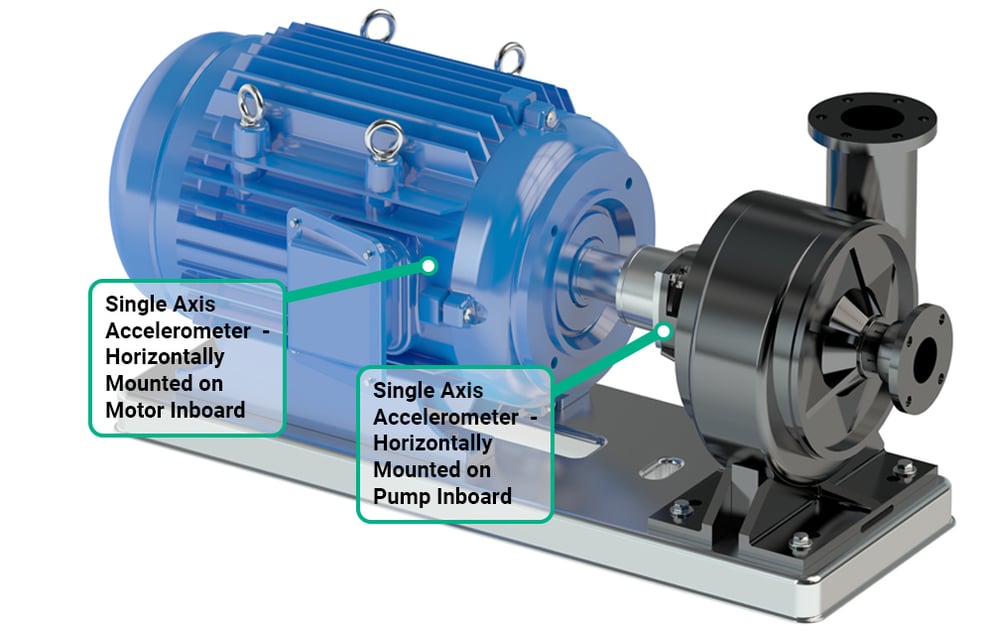

Montoring OptionsBasic Monitoring

Monitor two points with single axis accelerometers, mounted on the motor and load OR both on the motor. Sufficient to monitor and detect issues before they result in unplanned downtime.

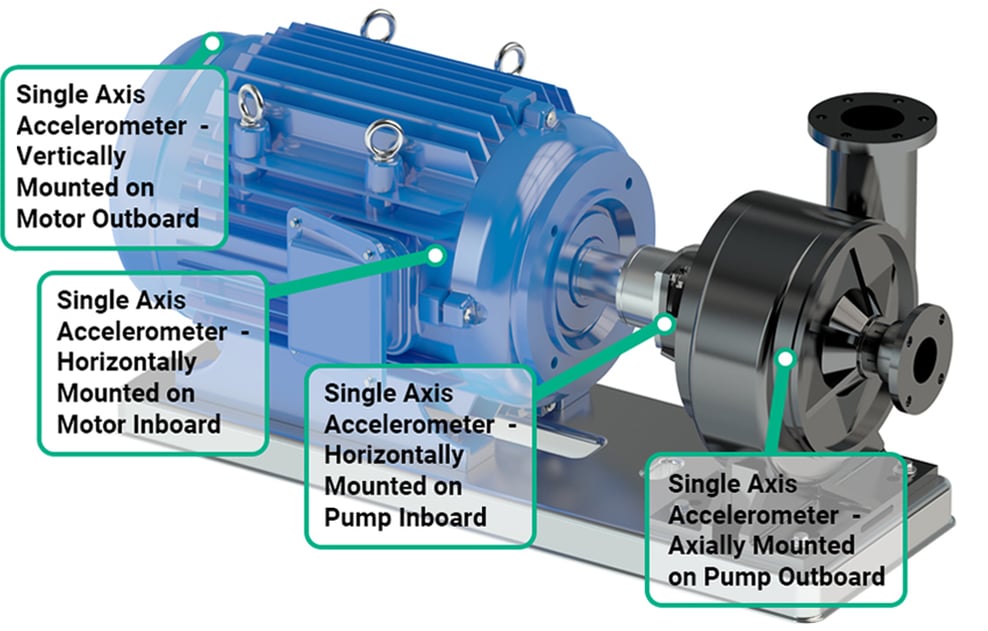

Montoring OptionsAdvanced Monitoring

Monitor four to six points, minimum of two on the motor and two on the load to provide additional coverage of machines that have a higher cost of failure if they go down. With the additional monitoring points, you will be able to detect issues sooner.

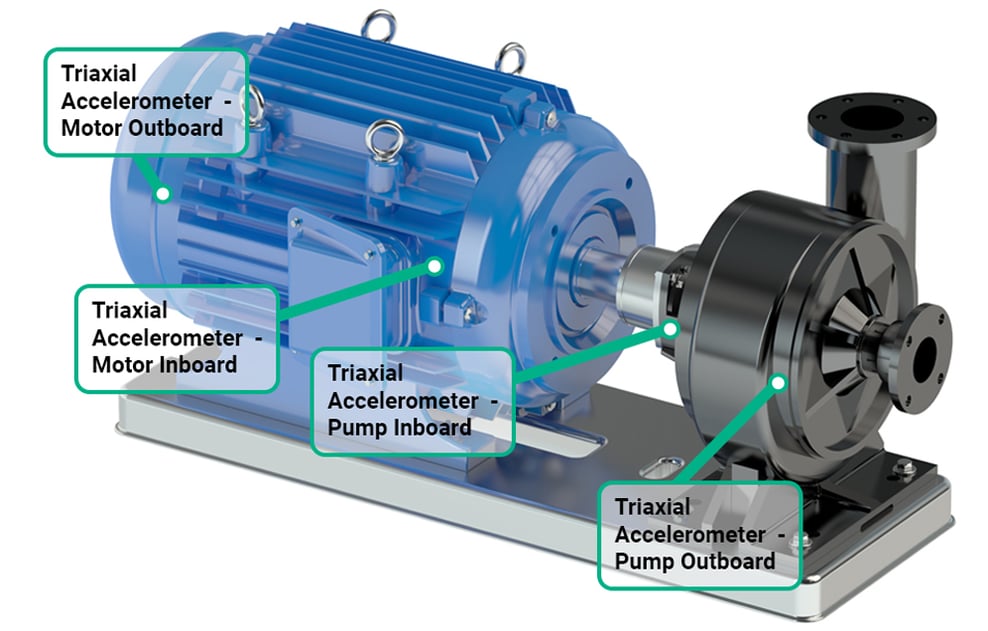

Montoring OptionsCritical Monitoring

By using triaxial accelerometers (which measure three points of vibration --- one each in the x-y-z axis), measure six points on the motor, and six points on the load to provide complete coverage of your most critical assets. With the additional monitoring points you will be able to detect issues sooner and have more detailed information on what needs attention.

Avoid the pain of unplanned downtime and take control with Analyst Inside

You know how to maintain your machines. But it’s those things that happen between maintenance cycles you don’t know about that cause the real trouble. With Analyst Inside you will be alerted to developing issues so you can get in front of them before they take the machine down. Keep all of your machines up and running as planned.

Your preventative maintenance plan does a pretty good job of keeping all of your machines in good working order. Maybe you’ve added some level of monitoring of overall process variables (such as pressure and temperature) to give you a heads up on potential issues that have developed in between maintenance cycles. But by the time an over-temperature warning gets thrown, it’s probably already too late. The damage is done and you’ve got an emergency repair on your hands.

Vibration monitoring provides the earliest insights into machine degradation. However, gathering and analyzing the vibration data can be challenging. An outside vibration monitoring service that records and analyzes data once a month runs the risk of missing a problem that arises soon after they’ve taken the data. Analysis by hand can be tedious and time consuming, and there’s a chance issues present in the data get overlooked. High-end vibration monitoring systems are too expensive to be cost effective for many applications. No wonder vibration monitoring still isn’t as widely used as it should be.

With Analyst Inside, you’ll get a solution that continuously monitors and analyzes the data using all of the same techniques that a certified vibration analyst would. As soon as a potential problem is detected, you’ll be notified with recommended actions to remedy the situation. All of the machine issues detected by Analyst Inside are stored for future reference. You can review all past issues to determine if the problems you are seeing on the machine are independent events or point to some underlying systemic issue. Furthermore, you can use the information to adjust your preventive maintenance program to avoid under-maintaining (not doing maintenance soon enough) or over-maintaining (doing maintenance that is not necessary yet)…saving time and money. The bottom line is you’ll have more data than you’ve ever had before about the performance of your machines.

But all of this information doesn’t have to be cost prohibitive. In most cases, Analyst Inside will pay for itself in a matter of months by avoiding those costly emergency repairs and helping to fine tune your preventative maintenance programs.

You deserve to have all the information you need to keep your machines running as planned. So schedule a 30 minute demo to learn more.

Schedule a DemoRead More